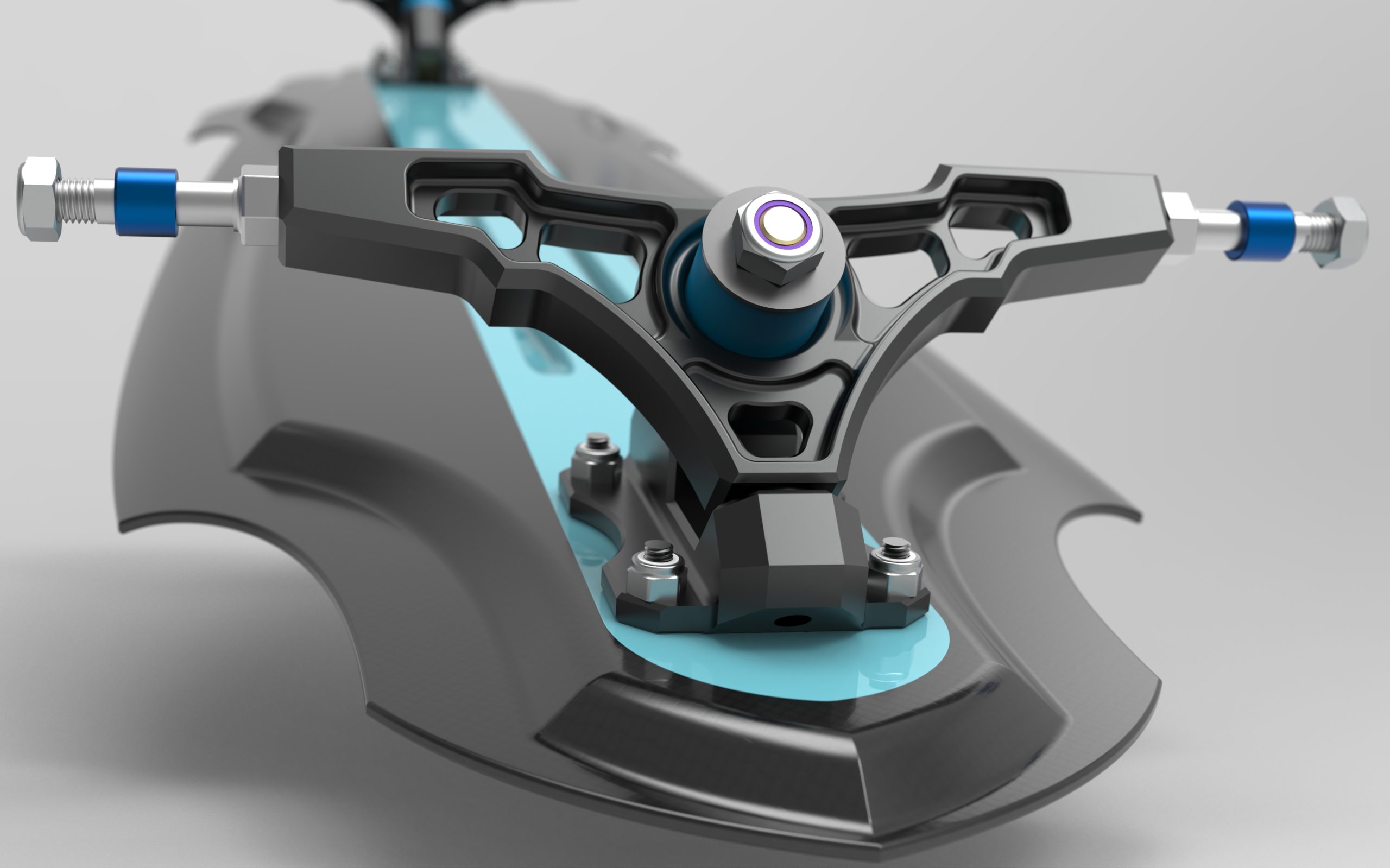

Bombshell Trucks

Role: Founder, Design engineer, Manufacturing engineer.

Directly after high school, while working at an aerospace machine shop, I used my knowledge from my day job as a CNC operator to start and operate a business named Bombshell CNC. For the three years that Bombshell was in operation, we manufactured precision long-board (skateboard) trucks for use in downhill and free-ride skateboarding.

The “P51” model trucks are comprised of 3 major components: the hanger, base plate and axles.

The hangers are machined from a solid piece of 7075 – T6 aerospace certified aluminum and have two threaded holes which receive a pair of axles.

The axles are machined from 17-4 grade stainless steel which undergoes heat treatment to achieve a rockwell hardness of C40.

The base plate holds the hanger and axles at a 45 ° angle and is machined from 6061-T6 aerospace certified aluminum.

For the center of the hanger, a bushing seat was designed using advanced surface modeling. This allowed for progressive support throughout the range of motion. These design features translated to a ride that was stable and predictable, two qualities professionals trusted when reaching speeds over 60 miles per hour.